INNOVATE

All Features Great and Small

Based on first impressions, it might seem strange to compare a suspension bushing—each individual piece no wider than five inches across—with a pair of chopsticks. There is, however, more common ground between the two than you may realize. As Mazda’s Yasuyoshi Mushitani explains, there is far more to suspension bushing than meets the eye.

Yasuyoshi Mushitani, Senior Principal Engineer at Mazda’s Chassis Dynamics Development Department, sits at a table within the research and development department at Mazda’s headquarters. On the tabletop, there are five pairs of hashi, or chopsticks, arranged in ascending order from the lowest perceived quality to the very highest. The first set is from a bento box set, the next from a convenience store, with the third and fourth from upmarket restaurants. The fifth set, remarkably, is a custom-made pair of handmade bamboo chopsticks, which have been altered and contoured by one specific user—Shunji Tanaka, the designer of the original Mazda MX‑5. It took Tanaka around 40 years to find the right design. The purpose of the five pairs is to enable Mushitani to describe the importance of suspension bushing: palm-sized, vitally important parts found in the suspension system of every vehicle.

The chopsticks, Mushitani explains, are the ideal representation of how responsive touch, even at the smallest level, can be utilized when driving. They are slim, tapered and lightweight, so that the user instantly knows how much pressure to apply and can receive instant feedback on the food the chopsticks are touching. Even the material used to manufacture the chopsticks can change how the food tastes and how the overall meal is perceived. Chopsticks, it’s said, should act as an extension to touch, rather than being a simple device for eating food. It’s these similarities, Mushitani believes, that align with Mazda’s philosophy toward suspension bushing and also help the driver feel more in touch with the road, in control and ‘as one’ with their vehicle, whether it’s tackling undulating roads, rough tracks, or tight corners.

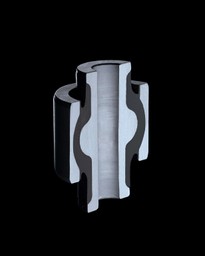

Bushing is a small, cushioning part of the overall suspension system that’s designed specifically to absorb bumps in the road, to reduce noise under the car, and to control the amount of movement the vehicle chassis experiences during a drive, particularly when cornering. These elements, it would be fair to say, are just as important as any of Mazda’s head-turning exteriors. That such a small part can play such an integral role is yet another wonder of engineering.

Each small piece of suspension bushing, with a few examples pictured, is vital for reducing noise, controlling movement, and cornering safely. (Image for illustrative purposes.)

For this, there’s Mushitani to thank. His vision for Mazda’s suspension bushing system was conceived shortly after he first joined Mazda in 1988. Although the iconic Mazda MX‑5 was released one year later in 1989, it was the Mazda Titan Dash that sparked his imagination when he joined the Chassis Dynamics Development Department. The Titan Dash was a commercial truck that rolled off the production line in 2000 and underwent a few adjustments by way of Mushitani’s expertise. Most notably, Mushitani planned to tweak the suspension bushing, so that the typical toughness of a commercial vehicle was altered to a smoother, more comfortable ride. “I changed just one bushing structure and I got a lot of improvement, not only in the vibration, but with the vehicle motion also,” he explains. “It’s a very small part but has a big impact on driving.”

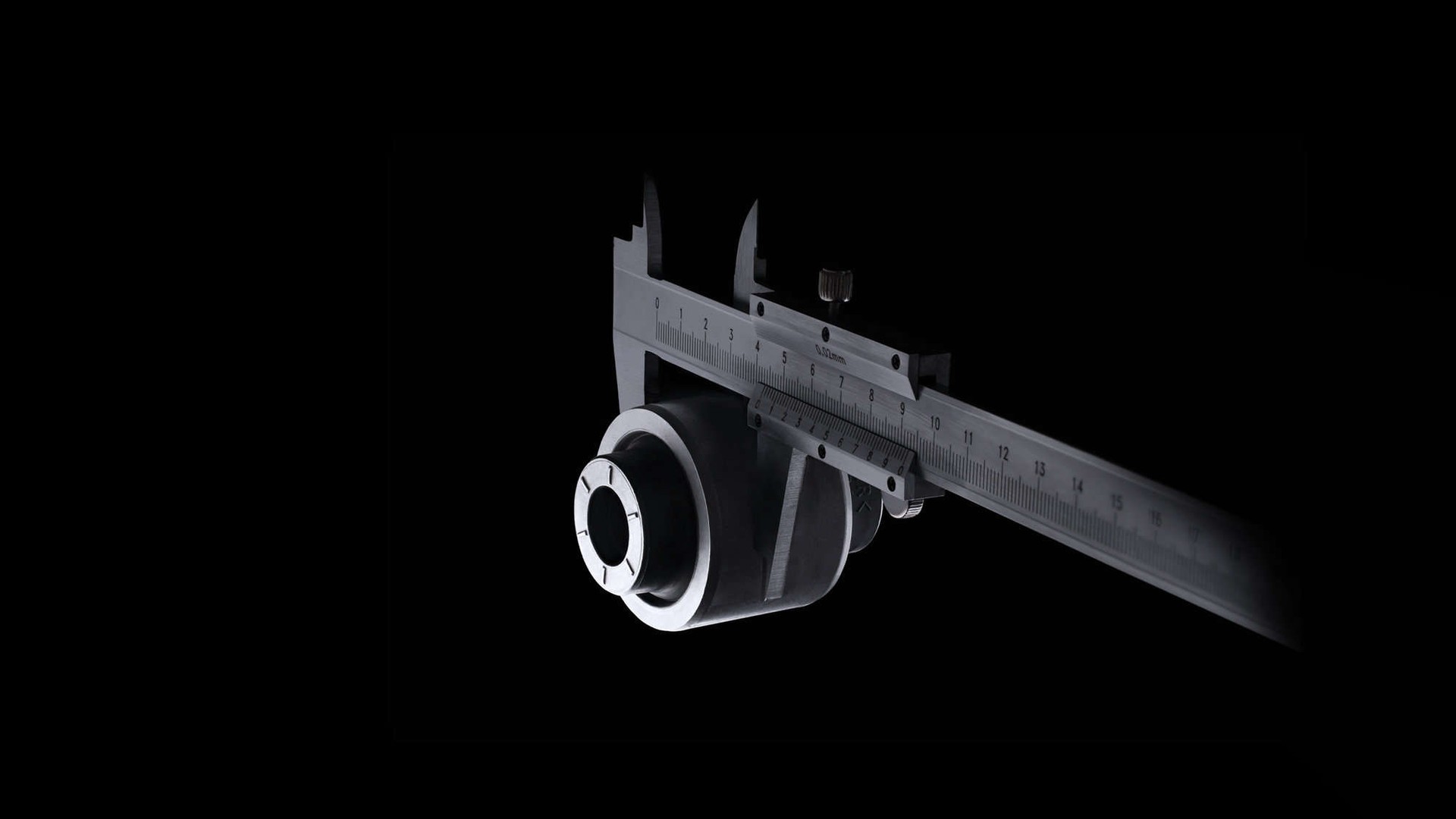

Over the past three decades, Mazda has developed Mushitani’s brainchild further, proving that the suspension bushing has a significant impact on driving experience, even when tweaked and tuned with only 0.1mm differences. It’s all about improving driver comfort, Mushitani explains, as well as playing additional roles in communicating with the driver and “contributing to safety,” he says. While other systems are created to shut out vibration and input reaching the driver, Mazda’s approach is designed to convey road surface conditions. This enables safer decisions to be made on the move, without causing any discomfort to the vehicle’s occupants, and Mazda’s innovative bushing development strikes the sweet spot between informative and noninvasive. Comfortable and safe, it provides true jinba ittai: the intuitive connection between a Mazda vehicle and its driver.

“We need to determine the geometry and configuration in the bushing, so we depend on the human sense. When it comes to bushing, it’s all about intuition and keeping things simple.”

What’s more surprising is that the process of making bushing isn’t all about machine-made parts. Rather, the human touch, as Mushitani describes, remains vital for ensuring the correct measurements and angles are used in each bushing prototype before manufacture. “We need to determine the geometry and configuration in the bushing, so we depend on the human sense,” he says. “When it comes to bushing, it’s all about intuition and keeping things simple.”

It’s this car-to-driver connection and communication that Mazda continues to champion. When it comes to bushing, it’s a mutually beneficial relationship between the vehicle and its driver. The vehicle, through the suspension, handling and dynamics, communicates with the driver, and the driver can make adjustments and remain in control. “The vehicle shouldn’t become too advanced,” says Mushitani. “Because if the performance of the vehicle is too good, the driver feels ‘driven’ by the vehicle—instead, they need to operate the vehicle themselves. This leads to our philosophy of jinba ittai”.

Words Ed Cooper / Images Lol Keegan

find out more